Next-generation 3D web platform to leverage CAD assemblies

Keeping the illustrations in the interactive part catalogue representative of the product shipped to the customer is essential to a great customer...

In this webinar hosted by Zea, Hal Trent, our Customer Success Engineer, and Michael Smith, our CEO, discussed the transformative role of content in selling parts in the manufacturing industry.

Collectively, they highlighted that accurate and aligned content supports the sales process and attracts customers, fostering trust and loyalty. This point was illustrated through a case study of the Acme Corporation, which faced significant challenges aligning its content with its parts catalog.

One innovative concept introduced during the webinar was using interactive parts catalogs and 3D models to bolster the customer experience, potentially boosting sales significantly. Hal and Michael debunked some prevailing industry myths, such as the notion that parts catalogs and servicing documentation must exist separately or that clients prefer PDFs over embracing advanced technologies.

The advantages of leveraging 3D content in the cloud were enumerated – foremost among them, the ease of updating, parts catalog automation, and simplified onboarding processes for new employees. They also stressed the critical role of maintaining data hygiene and establishing reliable data processes to ensure accurate and effective content.

Furthermore, the value of collaboration between content creators was discussed, emphasizing its importance for aligning servicing documentation with parts catalogs. They succinctly summarized technology as a supportive tool that can enhance content strategies but cautioned that it isn't a solution. Successful implementation of fresh technologies relies heavily on well-defined processes and a resolute commitment to problem-solving.

In the second half of the webinar, the discussion steered towards implementing technology and automation in small shops and construction projects. Here, the air compressor hammer was showcased as a tool capable of addressing the challenge of framing multiple houses with limited resources. However, the experts noted that understanding such tools appropriately is critical.

The webinar highlighted the need for defining a clear workflow and process when implementing technology. It also highlighted the advantages of commerce and using analytics data for improved decision-making. Integrating into an existing commerce environment was discussed as beneficial. The ultimate goal? To offer superior customer support, link content to sales, and conclusively prove the value of content in selling spare parts.

Zea is steadfast in providing top-tier commerce and content management software and services. For more information, don't hesitate to contact our team at Zea.

Hal Trent: On behalf of Zea, we welcome you to our webinar to discuss how to structure content to sell spare parts.

Content is crucial in driving spare part sales by attracting, engaging, and ensuring potential customers that the provided information matches their equipment. If your content is accurate and linked with your parts, it will help customers find parts faster and confidently place orders. The more confident they are, the more likely they are to purchase that part from your website.

Michael Smith: Hello, I'm Michael Smith, CEO at Zea, and I would like to piggyback on the comments that Hal brought forward in the introduction to this webinar. Every single industry has a content funnel. Teams create much content, directing people towards a product or service you sell. Following a decade in technical writing for a manufacturer, I realized that manufacturers already have a trained and proficient technical content team. Yet, manufacturers need an efficient and scalable way of linking that content to a spare parts platform and ultimately using technical content to drive spare parts sales.

High-quality technical information signals your audience that you're there to support them when the eventual equipment breakdown happens. It's also a way of building loyalty and trust with the customer. Demonstrating that you don't just show up for the sale but also invest in supporting the equipment throughout its lifetime will differentiate you as a customer-centric manufacturer, forcing your competition to play catch up. Strategically planning and executing a content architecture in this way will increase loyalty. Linking documentation that solves problems to spare parts will increase sales because of loyalty and because there's a high probability that, unlike aftermarket, you'll be providing the correct part.

Hal Trent: My name is Hal Trent. I'm a customer success engineer at Zea. I have been in the technical documentation field for over 15 years, working with companies ranging from Fortune 500 to startups. While working with these companies, I've had the privilege of seeing what their content workflows are like and then guiding them on how they're creating their content and how to align their content with their deliverables—breaking down content silos and engaging companies in a reusable content architecture.

We're not trying to have customers rewrite every manual. We're trying to get them to focus on their writing and how that content benefits the end user. Through these projects, we find more structure, better planning, and better process flow for content creation. Suppose all of this is mapped out before starting a project. In that case, you can start seeing how content affects different areas within the company.

Today, we will focus on how to structure content to sell parts. Still, in a traditional manufacturing world, I've often seen that parts catalogs, service manuals, and user guides don't align. We'll discuss what that means and present a story or use cases to demonstrate how you can get that content to align with your parts to get the best of both worlds. Ultimately, you want to create an interactive parts catalog that complements your service manuals and aligns the content in your service manuals down to the serial number of the equipment or the part number.

ACME has lent itself nicely and allowed us to tell a story about their project to improve their processes and build a new part catalog. We also want to debunk myths prevalent within the manufacturing and writing communities. These myths can be showstoppers for a project, as we’ll see in the story we're about to tell with ACME.

Mike and I have plenty of experience in parts catalogs. We've worked together at the BRP and want to bring you into a casual conversation yet ensure we hit the key points. So you might find us going back and forth. But we're trying to unearth the actual question or the real problem so that you have a solution to apply. To do this, we'll follow the story of Wiley Coyote as he tries to capture the Road Runner. And seemingly never being able to because of the equipment he's using.

If you remember the cartoon, Wiley Coyote constantly has his head in a parts catalog or some document, trying to figure out how to use the contraption to capture the Road Runner. Despite ACME's product claims, Wiley never captures the Road Runner. There needs to be more alignment between how to use the product he's paid for and received and how to repair it when it fails catastrophically.

Michael Smith: Let's take a tactical approach to changing these experiences; that is what we alluded to at the beginning, right? We will reimagine the role of the technical content creator (technical writer) beyond the traditional parts catalog, where just a part number and a description suffice. The vision is to bring B2C e-commerce experiences to the B2B world via a modern user interface and seamless browsing and checkout experiences. In this new user-friendly world, out-of-date 2D technical illustrations no longer suffice; you need to have an image, maybe multiple images of the part, to ensure you capture all of the information you can visually. 3D models are even better. Then, you'll have a name, a description, and extra information to help whoever's ordering that part put the right part in their basket.

Reimagining the role of the technical content creator is about bringing them out of the role of writing a procedure or documenting a set of instructions and leveraging their knowledge of the product to augment your customer's after-sales experience and use your spare part catalog to drive more sales. Secondly, we will discuss leveraging 3D to automate an interactive part catalog.

Manufacturers spend 75 to 80% of the cost to create a spare part catalog on labor to create an exploded view with callouts. Zea proposes an innovative approach where we can fully automate a spare part catalog using 3D models without creating any callouts. Removing callouts from the process enables a few things, like serial number-specific spare part catalogs at scale.

Finally, we will cover how e-commerce platforms help to sell more parts. It's a significant insight from the commerce community because most manufacturers need clear opportunities to increase revenue because they need to track all the sales that didn't convert. Currently, manufacturers receive and validate orders, then fill and ship the parts. Only a few manufacturers are tracking abandoned carts or monitoring missed upsell opportunities. Collecting sales conversion data and providing analytics into that data are things that commerce platforms are excellent at. We will present a framework in this webinar and a subsequent white paper illustrating how you can leverage the team you already have to drive quantitative data and customers toward your spare part catalog and increase your sales.

Hal Trent: Typically, we don't think of technical content creators as revenue sources or revenue teams bringing in actual revenue, but the reality is that the quality of the content can directly reflect revenue. The challenge is placing an ROI on the value of that technical content. For this project, we want to use technical content to sell parts purposefully. We start to see the metrics of that specific content and how it enables or potentially confuses customers when they're ready to buy those spare parts. Get into that mindset that technical content will sell. It has value. We look at Google, and Google is content, and they're very successful at generating revenue. So, as a technical writer and a content creator who has been in the industry for such a long time, I find it immensely important for companies to consider how technical communication and technical content are at the same level as a marketing campaign because that content truly does bring in value. It's harder to pinpoint the metrics for measuring a technical writer's ROI since the discipline isn't measured like a marketing campaign. We make it easier to measure by using content in an e-commerce system where we have those metrics.

Let's transition to the story of ACME Inc. Those familiar with ACME know that its business is centered on supporting one primary customer, Wiley Coyote; he spends enough money with ACME where they only need that one client. The problem is that ACME's products need to be helping Wiley catch the Road Runner, which they aren't.

ACME is asking itself where it wants to be in five years. They're trying to understand if the issue is at ACME's level or with Wiley Coyote.

ACME is in one of those situations where they ask if Wiley can't catch the Road Runner because he is not intelligent enough or if ACME's products are underperforming.

ACME wants to ensure Wiley is successful and is not constantly facing failure because, eventually, a new company will pitch their products to Wiley. ACME determines they can do a better job with their information their technical content, allowing Wiley to find the spare parts he needs to fix his products and find the information on how to use those products, all of these things that go towards the end goal of creating a successful customer experience. It's essential to look within this story at how we get there.

The way that we get there is by defining the objectives. Next, we look at the problems that customers face or the blockers preventing us from reaching our end goal. We quickly realized there must be more connection between content and parts catalogs. Therefore, Acme needs to figure out how to solve that issue. They will find a guide, someone who has solved this problem before.

Zea is this guide. Zea helps ACME understand what's not working and proposes a content strategy to align technical documentation with spare parts so that together, they can start taking steps to solve the problem. Zea provides the software and strategy, but ACME needs to execute this plan.

In this story, we will learn how to implement Zea's plan that allowed ACME to support Wiley better and avoid costly errors.

Acme is a manufacturer of bespoke Roadrunner capturing equipment. What we mean by bespoke here is that they're manufacturing products that are meant for capturing roadrunners. They offer base solutions, but they also provide bespoke solutions on top of that. They sell equipment in multiple countries; even though we think of the chase between the roadrunner and Wiley only occurring in the American deserts, this is happening worldwide.

Wile E. Coyote and other Wiley's worldwide are after road runners, which means that ACME must be able to provide support for its products in multiple languages. Customers who are concerned about a product will want to find information in their own language. ACME produces manuals in different languages and for various use cases. ACME also needs to cater to its dealership distribution model (B2B) while ensuring that end-users have access to the appropriate resources to solve their problems when they arise.

Part of the requirements for ACME is to send parts requests by email or to their dealers. There needs to be a robust system to track Wiley's orders. He orders parts from the part catalog online, which generates an email. However, there needs to be a proper tracking mechanism, and he is left hoping that what he receives is what he needs. This is where we need to identify the initial problem. There are several points that ACME currently needs to include, which is preventing them from achieving their goals. The situation is such that Wiley has to frantically look through the catalog to find what he needs, which could be a better situation.

On the left, we can see the setting. We need to understand what the Predator is trying to achieve and what product they are using. Our investigation of Acme revealed that their products often fail or backfire catastrophically at the most critical moments. Wiley can only access parts through Acme's outdated parts catalog, which means that information won't be available if there is a problem with a particular product. This can result in Wiley working with incorrect information, like playing Texas Hold 'em with a deck of 51 cards instead of 52.

He needs the necessary information and the service manuals he has need to match the current catalogs for the manufactured goods he's dealing with. As a result, he can't be certain that the part he's referring to in the manual is the exact same part in the equipment he's dealing with. This is a serious problem. Wiley must decide at some point whether he should continue being a customer of ACME or not, as his goals are not being met.

Michael Smith: This is the point where the story begins. As Hal mentioned, we take some time to understand the challenges. Often, the manufacturer has pretty good 3D models for the equipment they manufacture, especially when it comes to bespoke equipment. Engineers have to validate that the design will meet the needs of the specific customer, and they usually do this by building a 3D model and validating it digitally before the equipment enters production. We have observed that the same 3D model is frequently used to create equipment documentation. This led us to question whether it could be utilized downstream beyond engineering and manufacturing, throughout the entire product lifecycle, including service and spare parts. Our initial inquiry with manufacturers is to examine the 3D models and the associated data. By adopting this approach, we would add after-sales content to the 3D models, enabling customers to replace traditional PDFs and tables of contents with an interactive, easy-to-use, easy-to-understand 3D model that quickly directs them to the information they need. This is why we emphasize content, as we will add value to the 3D model by providing customers with efficient access to information.

At Zea, we offer a success plan to address the specific pain points of each manufacturer. These pain points may vary depending on a manufacturer's unique equipment. For example, some manufacturers may have thousands of unique pieces of equipment AND they struggle to create content at that scale. They must adapt content to each permutation and combination of parts to maintain the equipment. Other manufacturers may revise the same product very frequently, resulting in many versions of the same product. By understanding the core needs of each manufacturer, we can help architect a solution that delivers on their objectives.

The first step towards achieving this objective is to take a step forward. Rather than thinking about how to roll out a solution to a hundred countries and thousands of models, we suggest starting with one piece of equipment. By doing so, we can understand the rules and processes to create and apply while answering questions as they arise that will enable scaling the solution to the entire product line.

Contrary to a manual approach that requires creating excluded views and callouts for each system, we are more interested in understanding the rules. By rules, we mean the guidelines that govern how content is created and presented for each piece of equipment.

Manufacturers must follow specific rules and processes to succeed in their industry despite their uniqueness. To help with this, we work hard to determine if a part is serviceable, its price, and if it sells as part of a kit. Manufacturers establish content guidelines and improve the quality of their data, which we refer to as "establishing good data hygiene." By building data into their processes, they can automate many tasks and provide a customized experience for each customer who purchases their equipment.

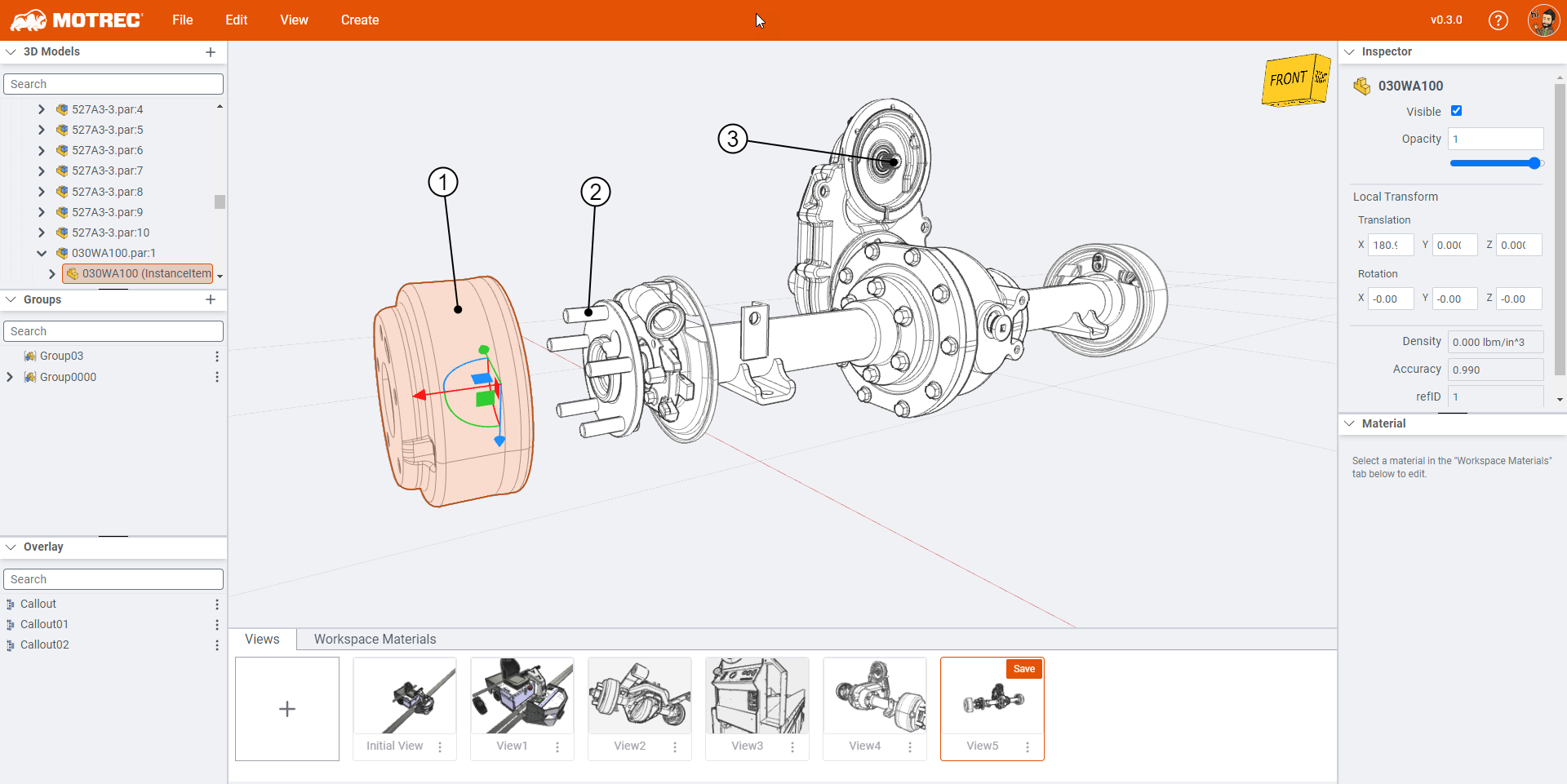

Let's look at three models from Motrec, a Quebec-based company, and their challenges. They have thousands of unique models, and creating a specific spare part catalog for each was not feasible with existing tools. Their options were to provide a generic manual that would create ambiguity or a specific catalog for each piece of equipment. They chose the latter to provide a better customer experience, saving time for both customers and support staff. Here are three models where an end-user can query the 3D model to find their parts.

In the first model, you will notice that we do not follow a system-based approach unlike traditional spare part catalogs. Although you can see systems on the left, we have provided an alternative approach to avoid the hassle of a system-based approach. It can be challenging to determine which part belongs to which system. Therefore, we have simplified the process by allowing you to jump straight into the ordering process. For example, if you need a switch, you can easily add it to your shopping cart without navigating through different systems.

Similarly, if you require a brake pedal, you can add the entire brake pedal to your shopping cart. This way, you can order parts from different systems without going forward or backward in a page structure, saving users time and effort.

It's interesting to know how we can find parts for a unique vehicle that is not a generic model. To explain this, let's search for parts on a different model. I'll return to the home page and enter a new serial number. As you can see, we have a slightly different model. It's a simple process. If you're a manufacturer, Zea can help you map those serial numbers to the correct 3D models and enable that interactivity for your customers. In this scenario, we would like to see what's behind it, and we want the USB charger. Let's add that and search for parts for one more vehicle.

For this model, let's keep things simple. We want this emergency button.

Let's go over some of the benefits that we were able to achieve with this project.

No manually created views for this project, which means that if something changes it's incredibly easy to update.

We don't have a complicated workflow of going from 3D model to some 3D authoring tool. From generating calouts that match a bill of materials to saving a 2d illustration to uploading To a spare part catalog software and publishing it to the web.

We've provided a solution that monitors engineering changes and synchronizes them daily. After which, they get published straight into the spare.

The part catalog is capable of rebuilding models on the fly. Any changes made will be reflected by simply refreshing the page as long as the changes have already been pushed to production. This approach allows the teams to automate the production of thousands of serial number-specific models, which would have taken years to accomplish with a content team. We've talked to other manufacturers interested in creating a similar system for their spare part catalogs.

However, this often turns out to be a multi-year project due to the different permutations and combinations involved. Moreover, this is often done by someone who is not a content strategist, so they have to learn how to single-source illustrations across multiple models through trial and error. This creates a problem of keeping track of the illustrations used in different catalogs, which becomes more complicated as the part changes or is replaced.

Our approach is to create these illustrations and build 3D models in real time, leveraging a single source of truth, much like a 3D content management system across all of your catalogs. Additionally, when manufacturers go through the digitalization process, the product documentation that is usually outputted, including warnings and setup instructions, is followed by several pages of exploded views and spare parts. However, we've noticed that manufacturers still publish their operator's guides and repair instructions, linking them to a dealer portal that hosts the 3D spare part catalog. This makes updates to the system easier, as there is no need to create new versions of the equipment documentation and send them to customers.

You must link your static setup procedures to your dynamic spare part catalog when organizing your content. This allows you to change pricing and part numbers and manage supersession strategies freely. By doing so, you can easily maintain and update your catalog while keeping your business running smoothly.

One last thing that we'll discuss in the myth discussion is the challenge often presented regarding experience. For example, a person with gray hair may be challenged by navigating a 3D spare part catalog. However, we have noticed that within just 20 minutes, even somebody who's very set in their ways is having fun and exploring the 3D model. They are learning a lot about the equipment almost intuitively through this. On the other hand, it takes about a year to onboard a new employee and teach them what the parts are. Every time we have presented them with a 3D solution, their jaws have dropped, and they have talked about how much less time it takes to onboard new personnel. We are talking about hours and, in some cases, minutes.

Hal Trent: Different opinions exist on using 3D parts catalogs in the manufacturing industry. While some believe they are the future's way, others still prefer traditional paper manuals or PDF catalogs. However, transitioning to a digital workflow where customers can visually select the needed parts can be beneficial. To achieve that, we need to separate fact from fiction.

Keeping the illustrations in the interactive part catalogue representative of the product shipped to the customer is essential to a great customer...

Users are free to purchase spare parts from anywhere, but the bottom line is that 3D sells more parts, and the original equipment manufacturer (OEM)...

So, you're a 3D CAD pro and you're probably thinking, "Why would I need an app like Zea to create 3D illustrations?" Well, let's break it down. We're...