Rising Demand for Parts | Motrec Launches 3D Interactive Part Catalog

Motrec, a leading electric industrial vehicle manufacturer offering genuine replacement parts, invests in providing accurate spare part information...

Users are free to purchase spare parts from anywhere, but the bottom line is that 3D sells more parts, and the original equipment manufacturer (OEM) is the only one with the original 3D files. The OEM has a clear advantage to exploit to increase their market share in a global auto parts industry of US$1.9 Trillion (if they’re in the automotive industry).

At Zea, we spend a lot of time thinking about what it takes to publish a great spare parts catalogue. To phrase our research and direct our thought process, we establish that the key differentiator of a great catalogue is a user-centric interface that reduces the time it takes to find the correct part. This post will go over the top 4 reasons manufacturers should choose to publish interactive 3D part catalogues.

When a manufacturer sells a product, they are selling that product’s up-time. The purpose of a spare part catalogue is to help the manufacturer deliver on its service promise by assisting users in finding and purchasing spare parts that keep the product in use.

Users are free to purchase spare parts from anywhere, but the bottom line is that 3D sells more parts, and the original equipment manufacturer (OEM) is the only one with the original 3D files. The OEM has a clear advantage to exploit to increase their market share in a global auto parts industry of US$1.9 Trillion (if they’re in the automotive industry).

All stakeholders want the sales process to be as frictionless as possible, meaning the catalogues have to stay up to date. Out-of-date or ambiguous part catalogues generate questions that a support team has to answer. As questions increase, profits decrease.

There’s a trend in technical publications towards on-demand content production, and the idea is to stop producing so much content before establishing the demand. The current best practice is to publish a part catalogue illustrating every serviceable part, but insights show that many parts will never be ordered during that product’s lifetime.

Consider not publishing a spare part catalogue at all; that’s what Motrec is doing. They don’t publish any content and instead provide a support phone number.

Like everything in life, establishing the optimal balance is critical. The hypothesized sweet spot is to produce content for serviceable parts that the manufacturer knows will have to be replaced.

It takes more time, effort, and investment to increase coverage beyond the sweet spot, and organizations find themselves with a diminishing return on investment. This hypothesis suggests that the manufacturer will maximize profit for all documented parts. However, if users can’t find the parts they need from the manufacturer, they will purchase them elsewhere, allowing the aftermarket to capture more of the OEM’s spare part business.

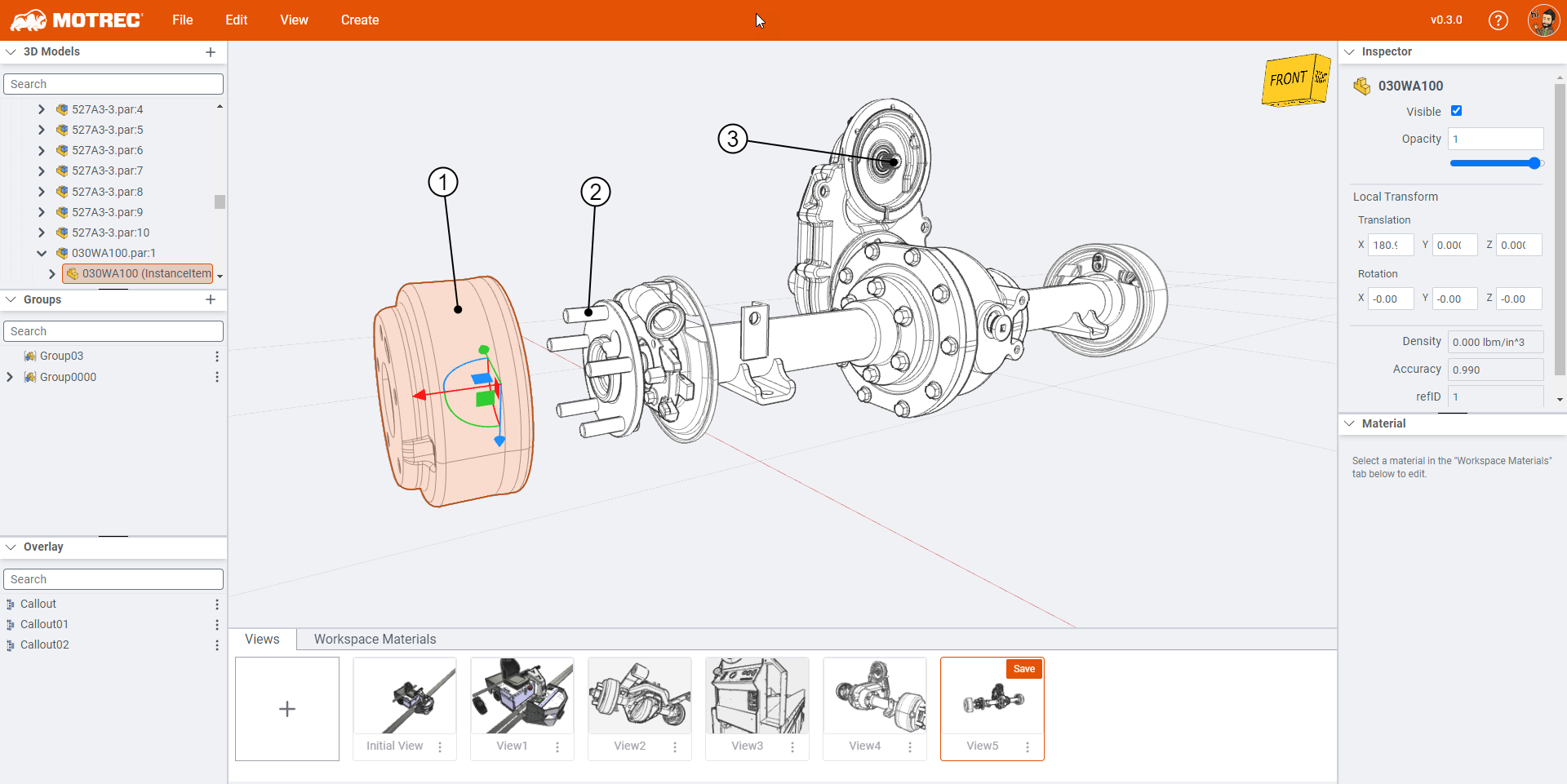

Interestingly, this problem only exists because we are still producing part catalogues the same way we did 20 years ago. Today, real-time 3D graphics engines can render geometry on-demand, which means that if you have a list of parts and a 3D model, we can produce VIN-specific illustrations showing all the parts applied to the vehicle (and hide everything else). This new approach would allow manufacturers to achieve 100% coverage without creating the exploded views ahead of time. Also, this means no more tedious hotspots.

Today’s process to create exploded views is bound by paper-based constraints such as specifying font size, creating callouts, paper space, illustration resolution (dpi), and export format (svg, png, etc).

Furthermore, since there is only so much you can display in a given paper space, this constraint forces the artificial creation and multiplication of vehicle systems only to have more explicit 2D illustrations. Just look at all the options (right-hand side of screenshot) that 3DVIA Composer has you choose from to export a technical illustration.

None of that matters in 3D on the web; the user is free to navigate, rotate, zoom, pan, select, and resize the model at will. Also, since the user can click directly on the model, we don’t need callouts and hotspots anymore. There is a simple rule-based system in the background that associates parts with a BOM ID.

2D illustrations require that a minimum of 4 software applications stay in sync:

Each bullet point above highlights a disconnect in the process. More streamlined processes make it simpler to onboard new team members and increase efficiency. Imagine the simplified workflow below. With a fully web-based 3D spare parts catalogue, we would:

Notice that we skipped several steps? We don’t need to author the exploded view if the model is interactive, as the users will navigate it themselves. We won’t have to add callouts since the 3D parts are clickable and associated with the BOM using a simple rule-based system. We don’t have to export anything since it’s already in the correct format and medium for the spare parts catalogue. And finally, since we embed the 3D model instead of uploading it to the spare parts catalogue, we can change it without re-exporting and re-uploading it.

It’s intuitive. Imagine no more guessing what system a part belongs to. Just find it in 3D, check the description, and add it to your shopping cart.

We are removing ambiguity as to where the part fits on the vehicle, the chances of a user adding the wrong part to the shopping cart drop dramatically.

Gartner explains, “As products become more configurable, the ability to complete a purchase with confidence becomes more challenging. Immersive technologies are being applied to bring clarity and confidence into the commerce process. Immersive technologies such as augmented reality (AR), virtual reality (VR), 3D video, and interactive rendering allow the user to better visualize or experience a configurable product. The best immersive technologies enable the user to interact directly and in real-time with the visual representation of the product” (Gartner, 2019).

A modern, fully web-based 3D authoring and publishing platform will replace the traditional disjointed pipeline of desktop authoring tools. The biggest question is where your organization is most comfortable on the adoption curve. There will be bumps along the way, but the first to market will not only provide an improved authoring and publishing experience to their clients but will also take market share from desktop 3D authoring tools.

If you have innovation in your DNA and want to create the future of spare parts catalogues. Get in touch; let’s make it a reality.

Motrec, a leading electric industrial vehicle manufacturer offering genuine replacement parts, invests in providing accurate spare part information...

So, you're a 3D CAD pro and you're probably thinking, "Why would I need an app like Zea to create 3D illustrations?" Well, let's break it down. We're...

Keeping the illustrations in the interactive part catalogue representative of the product shipped to the customer is essential to a great customer...