What is the difference between Zea and 3D CAD software?

So, you're a 3D CAD pro and you're probably thinking, "Why would I need an app like Zea to create 3D illustrations?" Well, let's break it down. We're...

Keeping the illustrations in the interactive part catalogue representative of the product shipped to the customer is essential to a great customer experience, but it’s complicated. It’s tricky because part catalogue authors need to work with several disjointed applications from multiple vendors to publish a parts catalogue. Each tool offers isolated gains but can’t significantly improve the entire process. Publishing an online spare parts catalogue is further complicated because the process comprises offline applications to generate the exploded views and online applications to publish the catalogues.

If the on-screen illustration doesn’t look like the part that needs replacing, there is a problem. The user will question whether it’s the correct part and will most likely contact the technical support team to verify the proper application before ordering it. This contact will drive up support costs in what should be a pure profit center. Without robust content management solutions, it’s impossible to deliver personalized experiences at scale.

Keeping the illustrations in the interactive part catalogue representative of the product shipped to the customer is essential to a great customer experience, but it’s complicated. It’s tricky because part catalogue authors need to work with several disjointed applications from multiple vendors to publish a parts catalogue. Each tool offers isolated gains but can’t significantly improve the entire process. Publishing an online spare parts catalogue is further complicated because the process comprises offline applications to generate the exploded views and online applications to publish the catalogues.

Typical information flow and software to create an electronic spare parts catalogue. All logos are copyright of their respectful owners.

Two of the biggest problems that manufacturers have to deal with to provide accurate product illustrations in online spare part catalogues are:

In this post, we’ll look at two divergent solutions for keeping illustrations up to date:

The best way to keep exploded views up to date in an online spare parts catalogue is to stop creating them in the first place. Yes, we’re proposing a workflow for producing and distributing personalized content alongside decreasing the time to publish and update content.

Why is Using a Global Part Database Important?

Because it saves time. Documoto, an online part catalogue solution, claims to “ease the burden of updating content through capabilities such as global supersession and content reuse” with their cloud-based solution. Picture Lion, a local Québec manufacturer of electric busses, produces several different models every year and tries to standardize parts as much as possible to benefit from economies of scale. A component like a screw will find itself on multiple models.

Imagine that the screw supplier decided to change the design halfway through Lion’s model year, and it now has to deal with a running change. A running change is when a portion of a production run is built with version 1 of a part, and the part is updated to version 2 during the same production run or model year.

The implications of a running change:

Think about how you would architect a solution to this problem. It’s much easier to provide an exploded view of an assembly that mentions it may not represent the precise model configuration like Subaru does in the illustration below.

This approach allows you to locate parts from a general perspective, yet when you click on the part in question, it shows you precisely the part you’re looking for. It’s the so-called best of both worlds, no need to update the exploded view for small changes, and all the exploded views link to the updated part information. Here is a rough architecture of the implementation.

-jpg.jpeg)

It’s much easier to update the detailed view and part information in one place and link to it than to update the illustration in multiple exploded views.

There are 2 problems left with this approach:

Up until now, all solutions assume that you need an exploded view in the first place. But you don’t, and you don’t need to force users to choose a system anymore.

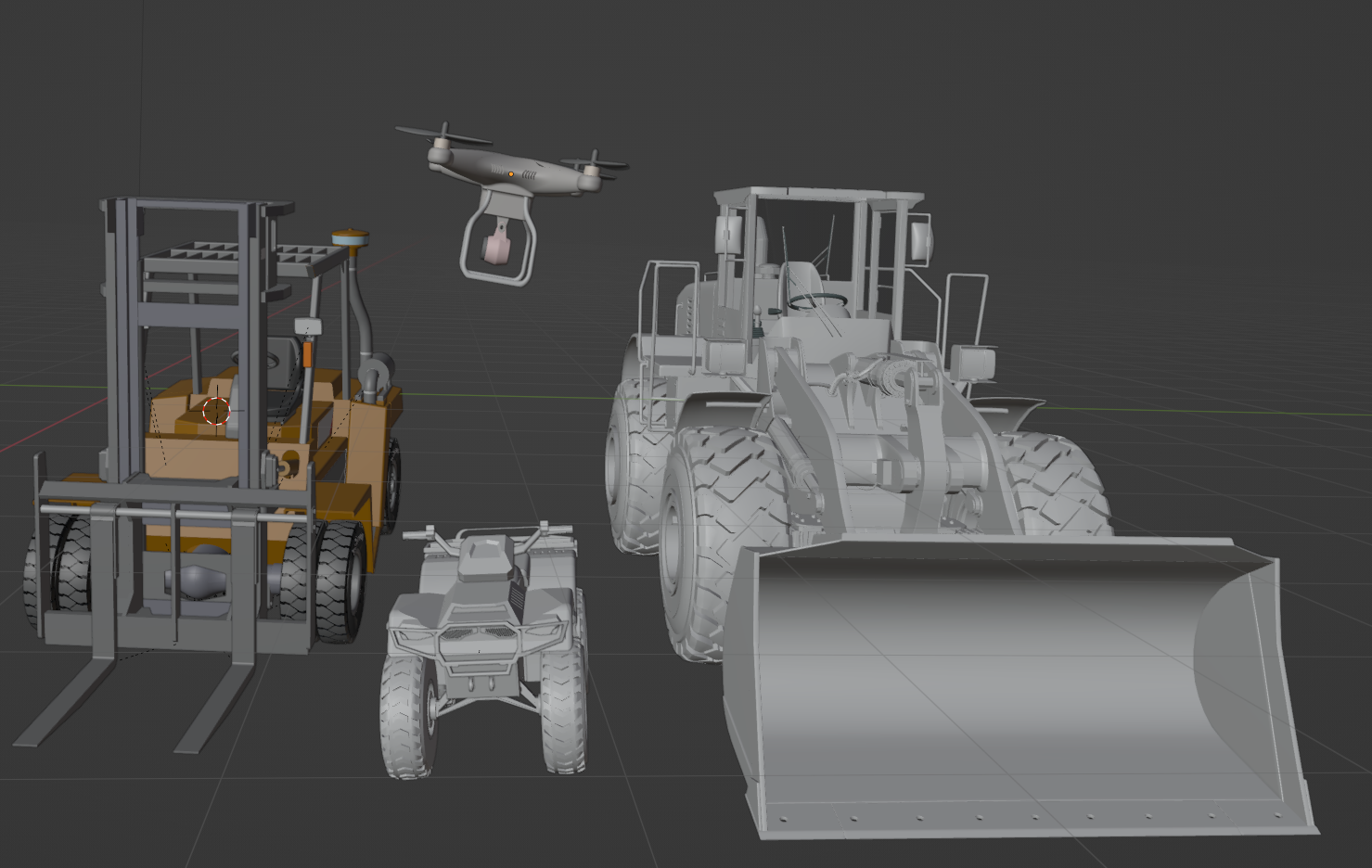

We asked around, and users prefer locating their parts on the 3D model instead of picking the right system or subsystem, clicking a callout, and getting their part information. It’s faster and more intuitive. This approach also comes with several advantages.

Exploded views are a result of a 2-dimensional constraint. Anybody looking up spare parts knows where the part is on the equipment but doesn’t necessarily understand the manufacturer’s classification system.

Users don’t care about or understand most manufacturer part classification systems or why a spare part ends up in one system instead of another. If the users can interact with a complete 3D model, they can find what they want.

Much like a database of part numbers and descriptions can deliver a single source for all part-related information, a database of 3D parts can provide a single source of information for all the illustrations presented to the user. This is what a PLM offers to engineers, so think of this as a web-based view-only PLM for spare parts. Once you remove sensitive engineering and manufacturing information from 3D models, they are essentially the same as an illustration.

The key difference is that you can automatically “draw” a 3D model in real-time based on the parts in the BOM.

Let’s take a look at how not to delight the user. If we had our way, we would use the VIN to generate a BOM specific to the vehicle and automatically draw the 3D model with the exact parts it was produced with.

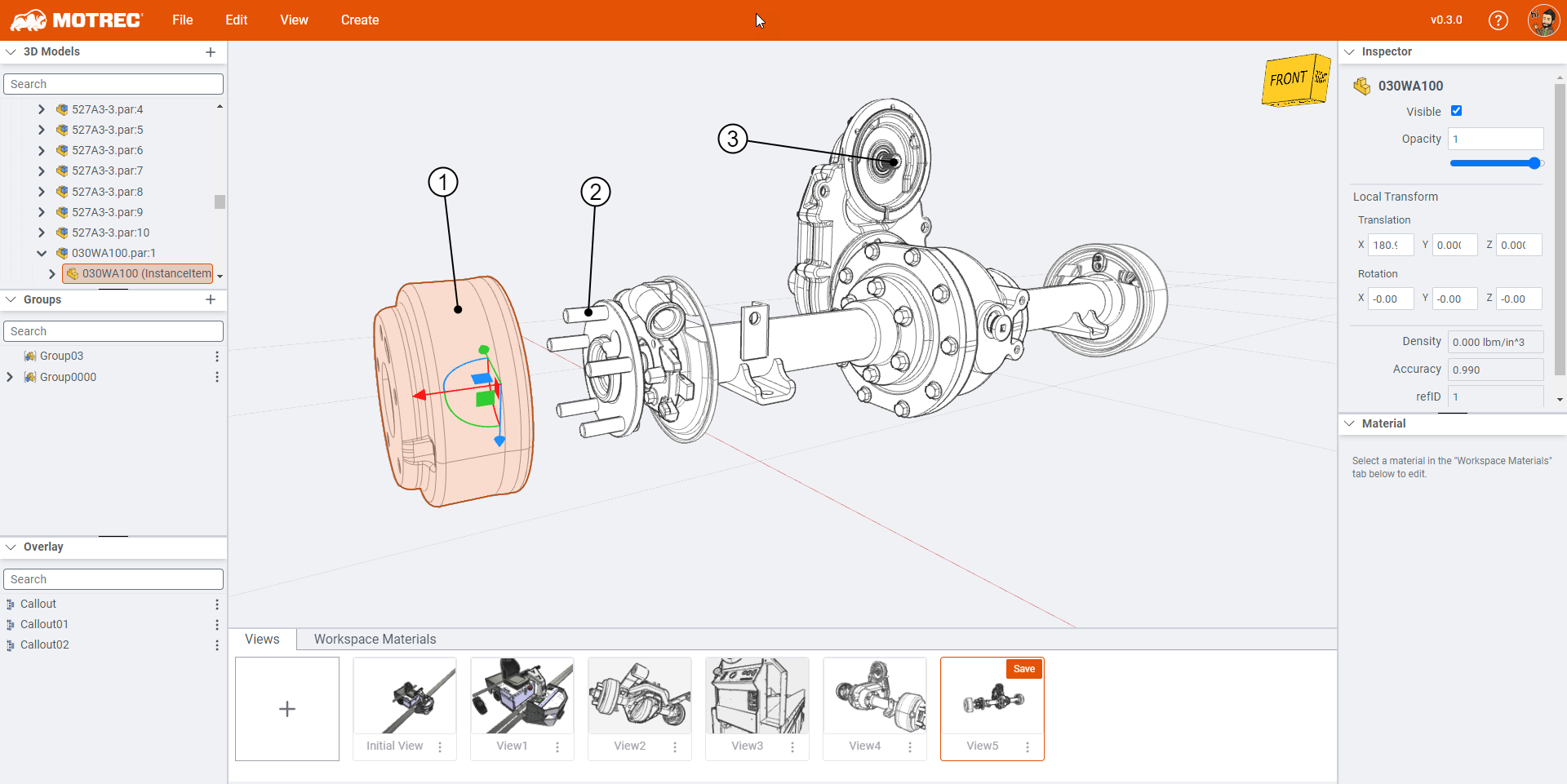

3D models are interactive, and users can click on a part to highlight it and get more information. Authors don’t need to create all those callouts and match them with a BOM.

-jpg.jpeg)

Check out some of these spare parts catalogues, in no particular order. They range from best practices in terms of database management and reuse to the most basic PDF catalogues.

If you want to deliver a unified, consistent content experience across channels during brand interactions, like AFTR, you need a 3D web-based Parts-Catalogue powered by Zea that integrates with your other software applications. Furthermore, producing and distributing personalized content should be a top priority alongside decreasing time to publish content updates.

We present new ideas to challenge the status quo but realize that sometimes they aren’t applicable. There is nothing inherently wrong with creating exploded views, but choose a cloud-based solution that integrates with your parts catalogue if you must make them.

We can help deliver post-sale content experiences that are every bit as rich as pre-sale marketing content experiences.

So, you're a 3D CAD pro and you're probably thinking, "Why would I need an app like Zea to create 3D illustrations?" Well, let's break it down. We're...

Users are free to purchase spare parts from anywhere, but the bottom line is that 3D sells more parts, and the original equipment manufacturer (OEM)...

Zea provides a next-generation 3D web platform to leverage CAD assemblies for downstream applications such as PLM applications, technical...